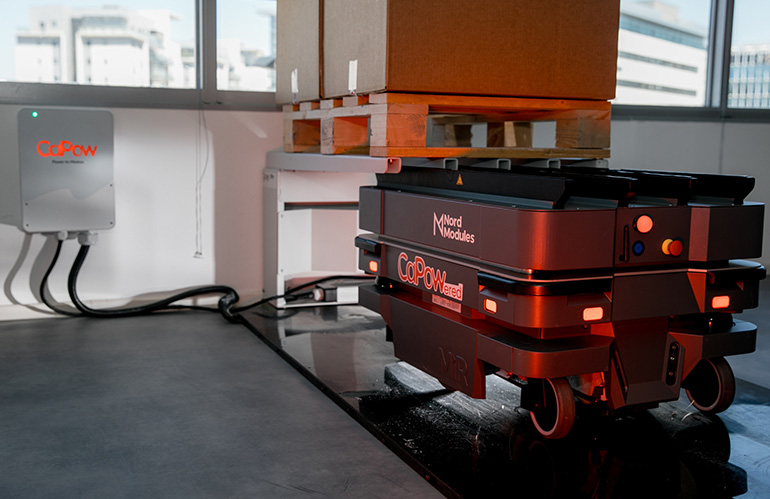

The Genesis platform allows for wireless charging of mobile robots along their operational routes. Source: CaPow

CaPow Technologies Ltd. last week said it has received CE certification for its Genesis power-in-motion delivery technology. The Be’er Sheva, Israel-based company said the CE Mark confirms its compliance with the European Union’s stringent health, safety, and environmental protection standards.

“This is a solution that has already proven itself in the U.S. market with commercial success and is now making its way to Europe,” stated Mor M. Peretz, co-founder and CEO of CaPow. “What truly sets us apart is our ability to deliver a unique solution that enables freedom of movement without the need for charging — something no one else offers.”

“Achieving CE certification is a major validation of our technology and our commitment to delivering safe, high-quality solutions to global markets,” he added. “As demand grows for more reliable and efficient power delivery in logistics and manufacturing, we are excited to provide European customers with systems that meet both their performance needs and regulatory expectations.”

CaPow said its wireless technology transfers energy to automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) as they move. The company claimed that this eliminates downtime and ensures constant throughput.

Modular charging stays robot-agnostic for easy deployment

CaPow has stayed robot-agnostic, serving maturing use cases in factories and warehouses.

“We’ve worked very hard to be agnostic to the platform — plug and play,” Peretz told The Robot Report. “There’s also an operational and psychological aspect. It’s harder to convince people [of the value of new automation], especially in conservative industries. We do a thorough discovery process, even before we see a facility.”

In addition, CaPow said its modular system easily integrates into existing infrastructure to maximize efficiency and reduce operational costs.

“Automotive manufacturers have told us that every minute that their production lines pauses costs more than $100,000,” said Peretz. “We’ve perfected the way we integrate into the facility with the aid of an algorithmic floor planner. We strategize with the customer where we’re going to put our stickers or pods along existing routes, and while we design that, we also create the tile-based process for integration. Installation doesn’t take more than 10 to 20 minutes overall.”

In May, CaPow partnered with AMR vendor Peer Robotics, and it quickly integrated its wireless charging system on-site at ProMat, recalled Peretz. It also demonstrated its new Genesis Antenna XL floor antenna.

The removal of downtime for mobile robots to charge means that fleets can be as much as 30% smaller, saving money, noted Peretz. He added that Genesis also removes the need for hazardous battery storage, saves space spent on chargers, reduces carbon emissions, and helps robot vendors scale across facilities.

CaPow tackles new markets

CaPow said the CE approval allows it to deliver Genesis to customers across the entire European Economic Area (EEA). The company added that its power system has already demonstrated measurable return on investment (ROI) for industrial automation clients in the U.S.

“CaPow is extending its footprint with significant customers, such as Hyundai Glovis,” said Peretz. “We’re heavily involved today with large-scale proofs of concept and deployments in sites nationwide. With Hyundai, it’s actually one of our first extensions into Asia, showing how OEMs can really focus on productivity while letting CaPow as the enabler to take care of their energy headaches.”

“We guarantee 100% uptime to 100% of the fleet today,” he asserted. “At Hyundai, we compared two sets of operations — one with CaPow and one without CaPow, and we executed in flying colors. A year ago, we deployed a few dozen robots at another automotive factory in the U.S., and since then, not a single robot has visited a charger.”

In March, CaPow raised $15 million to support its global expansion. The company is looking at charging for challenging cleanroom or cold-chain environments, but Peretz said that OEMs should be able to design their systems by specializing on the application rather than worrying about power.

Also, CaPow focuses on lower power levels than competitors such as Wiferion, enabling AGVs and AMRs rather than larger electric vehicles. Peretz added that CaPow could help power-hungry mobile manipulators and humanoid robots deliver higher utilization rates.

“We do hear from inventory robot and high-lift telescoping robot OEMs that they have to stop every few hours, which is a critical bottleneck, especially in goods-to-person [G2P] picking,” he said. “We are seeing interest in somewhat bigger machines.”